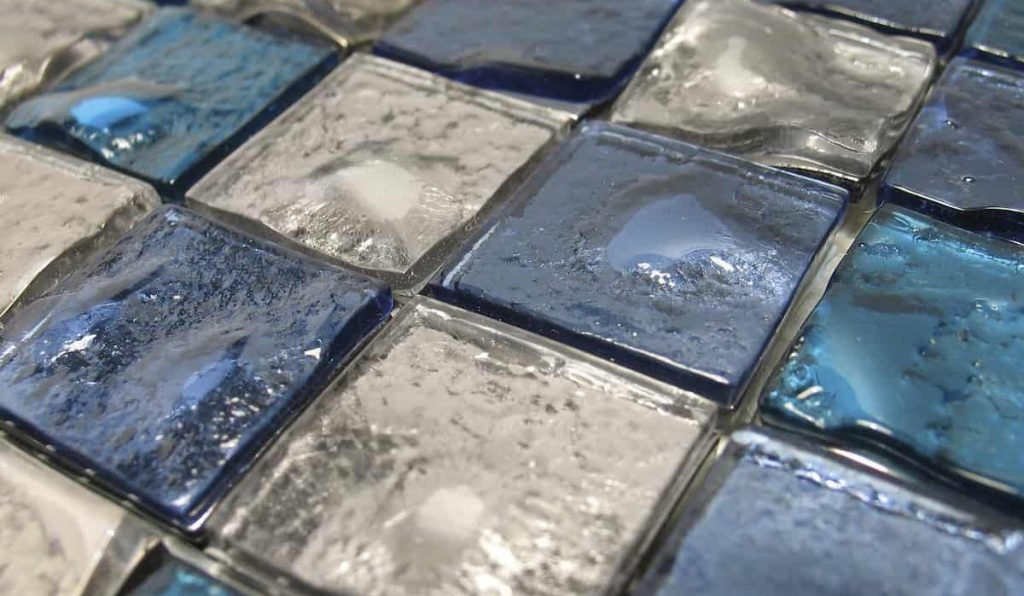

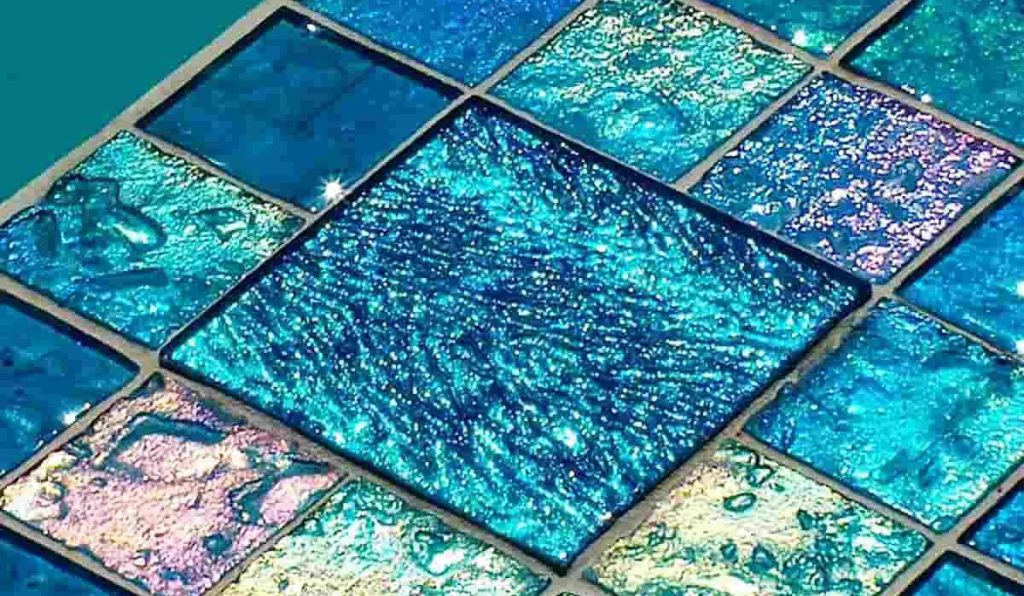

The glass tiles are a beautiful alternative to use as round back and washing near me, however, they are fragile and can be easily installed or cut by cutter.

In this section, we use the right methods for cutting glass tiles for projects with any size so you may avoid crushing these beautiful and long-lasting materials.

Glass tile is now being considered as an increasing number of owners tend to use it in home improvement projects that they do.

Since cleaning is simple and has a surface that is both glossy and durable, glass tile is a great alternative to use as a splash, on shower walls, and as accent in the bathroom.

The primary allele of the glass tile is that, compared to the ceramic tile, it can have a clear brightness or gem-tondi that is able to reflect light and often create a stunning effect.

The owner can often do the installation, and this does not involve much of the work of the belt. However, since the glass tile is made of crushing-prone material, the tile cutting process may be difficult.

What is the most effective method for crushing glass tiles? The answer depends on the size and type of tiles in the project.

The wet saw, trolley, strip cutter and wheel-mounted mosaics are the four ways we described in this guide for cutting glass tiles. “We did it so we could prepare for any possibility.

Note: Before starting the installation process, it is recommended that you first design a dry layout of the tile pattern you use. Before you permanently attach tiles to the wall, you’ll have the opportunity to rehearse and complete replacement of tiles if you do. Remember to make tiles in areas where the edges of the fragmented are less obvious, such as at the top of a back-end where the tiles reach under the cabinets. This will ensure that the edges of the cut will not be removed from the overall look of the tile.

If you arrange a large area that requires multiple straight cuts such as showers, you will find that the wet saw is very useful. Wet sawing is a fast process that creates sharp edges in addition to reducing the possibility of damage to glass tiles.

A constant stream of water is discharged from the saw while it is cut through the tile, reducing friction and cooling the cutting edge. As a result, this cutting will be more accurate and more probable.

The price of one of these strong saws can range from about a hundred dollars for a more affordable model to over one thousand dollars for a high-level contractor tool.

If you don’t want to spend a lot of money on buying a saw that you’ve only used once or twice, you can apply to rent that shop specializing in renting construction equipment or even in the center of big houses in your neighborhood if you live nearby. A high quality wet saw can be purchased for $500, but you may rent one for approximately $50 a day.

In the days before the tile was built, skilled artists had to cut thick glass by hand to make glass windows and colored glass mosaics. Even though it takes more time than a wet saw and is more likely to cause imbalanced failures, the professional tile group today also uses the manual cutting method of glass tiles, especially when cutting small tiles.

Handheld glass wheels have a reasonable price starting from about $15 per wheel (see on Amazon). In addition, you have a pair of pliers (which may be seen on Amazon) or a pair of pliers (see on Amazon).

Both are inexpensive tools that are specifically designed for use with glass. Before starting the project, when you have all the necessary equipment, you must first take a few glass tile samples to be familiar with the amount of force required, flowers and crushing.

Because the machine can cut the tile in one move, using load cutting to cut glass tiles is more time and more efficient work than using the mud wheel and plier.

(There are bar cuts that only point to the tile, but also bar cuts, which have a pressure foot that breaks the tile along the score line.) Load-like slicers start one by about 25 dollars (you can see an example of that on Amazon) and the prices go up there. Models with higher price tag usually include measuring tools for cutting precise angle as standard equipment.

Mosaic nippers are commonly used to cut small pieces of glass in irregular shape so that they can be used in creative designs. Even if getting experience on a few spare parts before moving to the next step with any approaches described here in particular it is necessary to do some practice with this method.

Niping lacks the precision of other cutting methods such as scoring or cutting with wet saw. Wheeled nippers are very similar to common pliers, however, rather than having a flat head, this $15-dollar tool (can be seen on the Amazon) has high and low-end carbide wheels designed for cutting through glass.

Glass tiles cannot be installed on straight lines when performing this work around a pipe or any items with a curved shape.

However, if you use scoring tools, wet saws, pliers and grinding stones, as well as combining some of the methods described in the previously provided paragraphs, you can create a smooth curve.

Get your cut after marking it with a washable indicator.

After using a washable indicator to create a curved line on the glass tile, the portable glass tool will be carefully pushed towards you along the guide created for the tile score.

Take your time and be as accurate as you can in your work, because you will most likely do so without your hand and without the help of a straightener to guide the tool.

It is cut straight and perpendicular to the line that has already been achieved.

Start from the edge of the tile that you want to discard, several straight cuts (about 3/8 inches distance) using wet saw, working perpendicular to the score line.

The space of the two is approximately 3.8 inches apart. Because of these cuts, the resulting glass will be in the shape of a blade.

As you get closer to the edge of the curve, your smooth cutting lengths start to decrease.

Remove these spokes from around the cutting of pipes and separate them.

With small pliers, remove the thin rows of glass at a time so that only what remains is the curved glass tile.

Before installation, make sure the edges are smooth.

Using a scrubbing stone, smooth and polished cutting. After using a wet cloth to remove glass chips and markers, the tile will be ready to be on your new smooth surface.

Your comment submitted.